The last decade has shown a clear tendency to the structure complication in new therapeutic molecules of both biological and chemical origin. Typically, such complex molecules with many chemical groups are unstable, easily oxidized, hydrolyzed and are subject to other degradation processes. Therefore, they should not be stored in solution for a long time. At the same time, their release in the form of tablets does not always solve the problem, because often such compounds have low bioavailability and are easily destroyed in the gastrointestinal tract. In fact, the only solution for such substances is to manufacture them in the form of parenteral powders. That is why YURіA-PHARM is actively developing products in this dosage form.

Lyophilisates

Is the world’s most common form of parenteral powders. Its advantage is in the minimal degradation of the active substance, because the drug solution is frozen almost immediately after preparation and then sublimated under vacuum at low temperatures. Before the use, the lyophilisate dissolves instantly after the addition of the solvent, so it can be administered to the patient immediately. The main disadvantages of the technology are low productivity, high energy consumption and cost of the process.

Powders

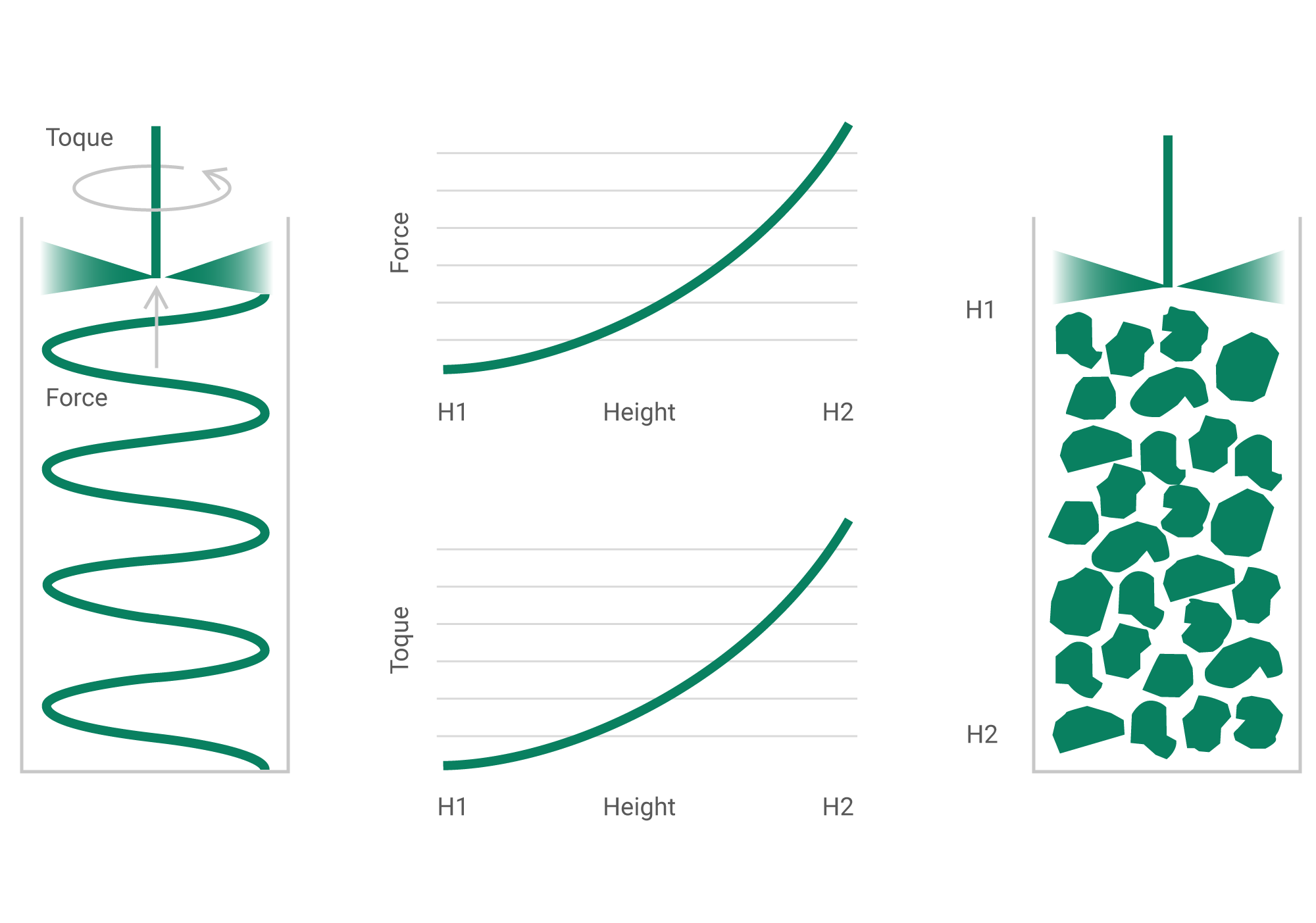

dried by spraydry technology in aseptic conditions. This is a relatively new technology that allows to get a sterile powder product. This technology makes it possible to control the structure of powder particles (particle engineering). In particular, it is possible to set such parameters as size and shape of the particles, their density and structure, to apply some coating. The use of organic solvents to dissolve substances instead of water may speed up the drying process and minimize the hydrolysis of the product.

Most substances produced in the form of parenteral powders are prone to degradation, so during their development we focus on actions that prevent the destruction of the substance and the formation of impurities. This is achieved by controlling the products of degradation at all stages of production and by selecting optimal parameters of the technological process, using the Quality-by-design approach.

Equipment used for the development of parenteral powders in the laboratories of YURіYA-PHARM R&D includes a laboratory freeze-dryer and a spray dryer from leading European manufacturers. To determine the polymorphic shape of the crystals and the eutectic temperature of lyophilisates, a differential scanning calorimeter (DSC) is used. The particle size distribution of the obtained powders is studied with the help of a laser diffractometer. To control the obtained product quality, we actively use analytical equipment (chromatographs with different types of detectors, automatic titrators, etc.)..